What is Stainless Steel Sheet? Properties, Uses, and Composition

Stainless steel is a widely used metal alloy with unique properties, making it popular across various industries. One common form is the stainless steel sheet, which is utilized in many applications, from household items to heavy-duty machinery.

Properties of Stainless Steel Sheet

Physical Properties:

- Corrosion Resistance: Stainless steel sheets offer superior corrosion resistance due to their high chromium content, which prevents rust and corrosion.

- Mechanical Properties: They have high tensile strength, ductility, and malleability.

- Chemical Resistance: Stainless steel sheets are highly resistant to many chemicals and stains from food and beverages due to their low permeability to liquids and gases.

- Hygiene: With excellent hygienic characteristics, stainless steel sheets are ideal for use in food-processing industries where hygiene is crucial.

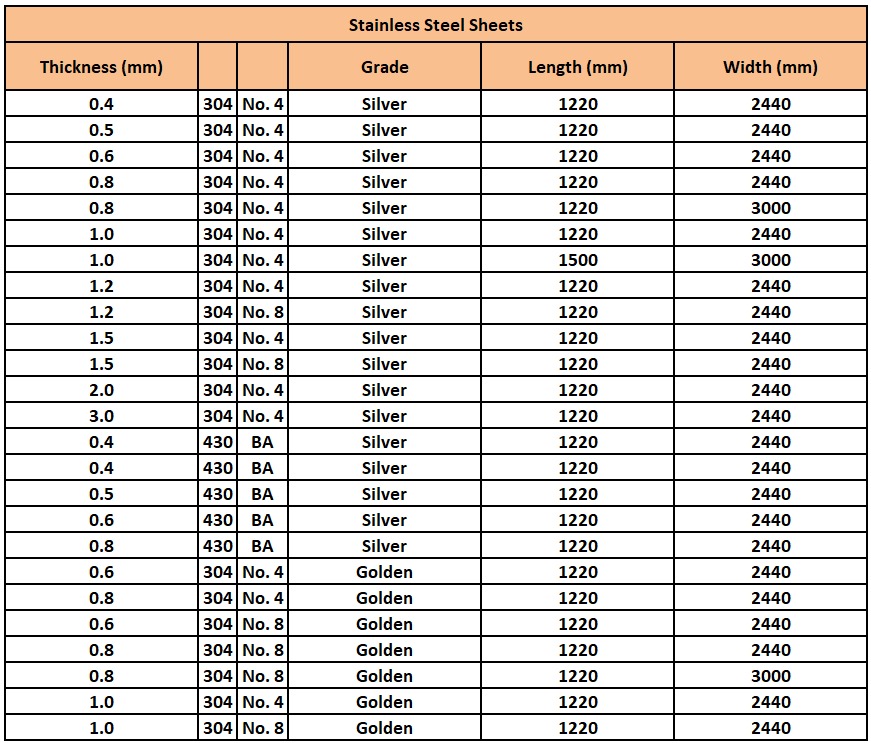

Stainless Steel Grades and Applications

| Grade |

Application |

Properties |

| 304 |

Architecture (interior & exterior); food processing; hospital equipment; household appliances; brewing & dairy equipment; heat exchangers, etc. |

General-purpose austenitic corrosion-resistant steel. Can be polished to a high finish. Weldable up to 12mm without subsequent heat treatment unless needed for stress purposes. |

| 304L |

Chemical plants; food processing equipment; coal and petroleum industries. |

Extra-low carbon austenitic stainless steel with greater resistance to intergranular corrosion than 304. Can be welded in greater thicknesses without requiring heat treatment above 500°C. |

| 316 |

Exterior applications in severe industrial/marine atmospheres; chemical & textile equipment; wine vats. |

More resistant to certain corrosive conditions than non-molybdenum stainless steel. Suitable for chemical manufacturing equipment. Weldable up to 12mm without subsequent heat treatment. |

| 316L |

Chemical plant and food processing equipment. |

An extra-low carbon version of 316 with similar corrosion resistance. Can be welded in heavy sections without inter-granular corrosion, making it suitable for polishing to a bright finish. |

| 430 |

Interior architecture; automotive trim; domestic appliances; restaurant equipment. |

A 17% chromium stainless steel. Good resistance to normal atmospheric corrosion. Suitable for forming, drawing, and various chemical applications like nitric acid and ammonia. Welds tend to be brittle, and resistance to scale and oxidation is satisfactory up to 800°C. |

Stainless steel sheets are incredibly versatile and offer numerous advantages across multiple industries, including architecture, food processing, chemical manufacturing, and more. Understanding the different grades and their properties helps in selecting the right stainless steel sheet for your specific application.

Finish Description For Sheet & Plate

A. Mill Finishes

| FINISH No. |

DESCRIPTION |

REMARKS |

| 1 |

Hot rolled, annealed and pickled. (HRAP) |

Generally used when smoothness and uniformity of finish are not important. |

| 2D |

Cold-rolled, softened and de scaled. |

A uniform, matt finish. |

| 2B |

Cold-rolled, softened, de scaled and lightly rolled on polished rolls. |

A smooth finish for general applications. A brighter finish than 2D. |

| BA |

Bright Annealed. |

A cold-rolled reflective finish retained through annealing. |

B. Mechanically Polished Finishes

| FINISH No. |

DESCRIPTION |

REMARKS |

| 3 |

Ground. |

A uniform finish generally obtained with 100-180 grit size. |

| 4 |

Polished with 120-240 grit. “Brushed”. |

Has a grained texture, not highly reflective, which is suitable for general purposes. Meets international 3A standard of hygiene. |

| 8 |

Polished. Mirror finished for reflectiveness. |

Has a bright reflective finish with a medium degree of image clarity. |